© Copyright 2009 NetMotion, Inc. All Rights Reserved.

Why Advanced Materials?

Advanced materials and polymer plastic screws have many benefits over traditional steel screws such as:

-

1.Low gravity and very light weight (polymer plastic) of about 1/5 to 1/6 vs. metal screws

-

2.High electric resistance and strong electric insulation for plastic screws

-

3.Corrosion-proof characteristics for plastic screws

-

4.Thermal conductivity is minimal with good adiabatic performance for plastic screws

-

5.Anti-magnetic characteristics for plastic screws

These materials are being used in electronic devices around the world such as mobile phones, radiation equipment, chemical processing, aerospace and many other key markets. To find out more about the markets and usage of these materials, click here.

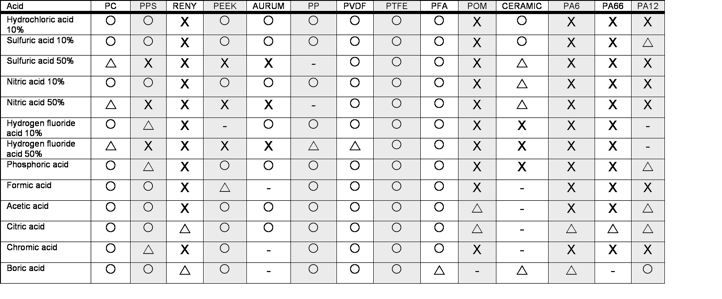

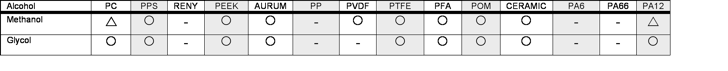

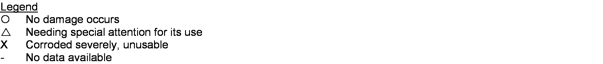

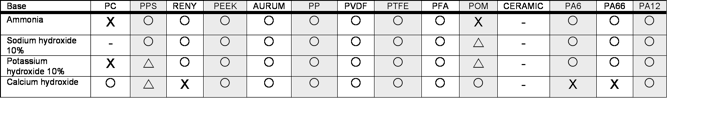

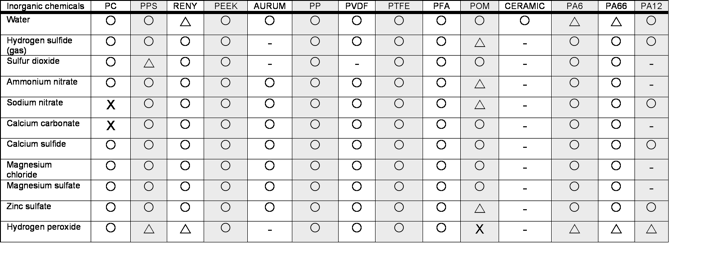

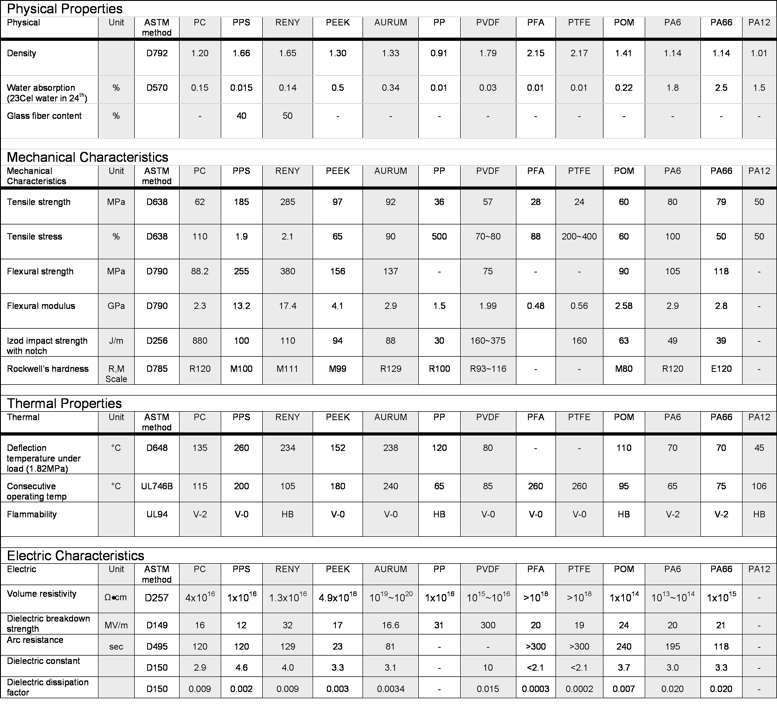

The tables below list out the physical comparisons of different materials as well as their chemical properties for you to select the best material for your application. Please note: All information is for reference only and actual usage and properties are dependent on specific implementations.

Chemical Resistance

Advanced Material and Polymer Plastics:

PC-Polycarbonate: One of the most impact-proof polymer plastic materials, maintaining its strength in temperatures reaching -40˚C. Strong UV protection with applications in external conditions.

PPS-Polyphenylenesulfide: Exhibits strong thermal properties as it operates at 200˚C for consecutive operation. Chemical-proof to almost all acids and alkali except undiluted nitric acid. Consistent dielectric rate over a broad spectrum of frequency and temperatures.

RENY-Glassfiber Reinforced Polyamide MXD6: Has the most strength and elasticity of polymer plastic materials. Chemical-proof in lubricating oil, gasoline, organic solvent and alkali.

PEEK-Polyetheretherketone: Exhibits strong chemical-proof properties. Friction-proof and abrasion-proof properties for fluid processing. Also anti-magnetic for radiation, medical and aerospace.

AURUM-Polyimide: One of the lowest outgas characteristics under high temperature environments. Exhibits both heat-proof and chemical-proof properties.

PP-Polypropylene: Gravity of 0.9 is the lightest of all polymer plastics. Also used for sterile environments due to its hydrolysis-proof properties. Key market is electronics due to insulation-proof and dielectric properties.

PVDF-Polyvinylidenefluoride: Exhibits chemical-proof and weather-proof characteristics. Used in electronics industry, fishing lines, and for musical instruments.

PFA-Perfluoroalkoxy Resin: Provides creep resistance at high temperatures as well as low-temperature toughness. Chemical-proof properties utilized in the semiconductor industry.

PTFE-Polytetrafluoroethylene: Is an inert agent in most chemicals and solvents. Exhibits non-cohesiveness and lubricity properties.

CERAMIC: Exhibits friction-proof, high hardness, stable dimensions with a very low coefficient of thermal expansion. No outgas under high temperature environments.

POM-Polyacetal: Exhibits fatigue-proof, creep-proof, friction-proof, and abrasion-proof properties.

PA-Polyamide: One of the best friction-proof and abrasion-proof characteristics of any polymer plastic. Oil-proof in gasoline, mineral oil, and ketone. Gas-permeability (oxygen, nitrogen, carbonic acid gas, etc.) is very low.

NetMotion, Inc.

3350 Scott Blvd, Bldg 24

Santa Clara, CA 95054

Tel: 510.578.2808 Fax: 510.743.4130

Email: sales@netmotion.com